It is a heat-treated glass which is several times stronger than ordinary annealed glass.

Tempered glass is manufactured by heating up the float glass to a high temperature, then blowing air onto its surface, cooling it down swiftly and uniformly.

Feature

- On the same thickness Tempered Glass has bending and impact strength which is 3 to 5 times higher than that of ordinary glasses.

- As resistant to rapid temperature changes (thermal shocks), Tempered Glass is approximately 3 times as ordinary float glasses.

- When broken, Tempered Glass will shatter into small pieces to prevent serious injuries.

Applications

- Frameless tempered glass doors

- Curtain walls

- Shop fronts

- Windows

- Showcase

- Escalator side plates

- Elevators panels

- Balustrades

UV Control

UV Control

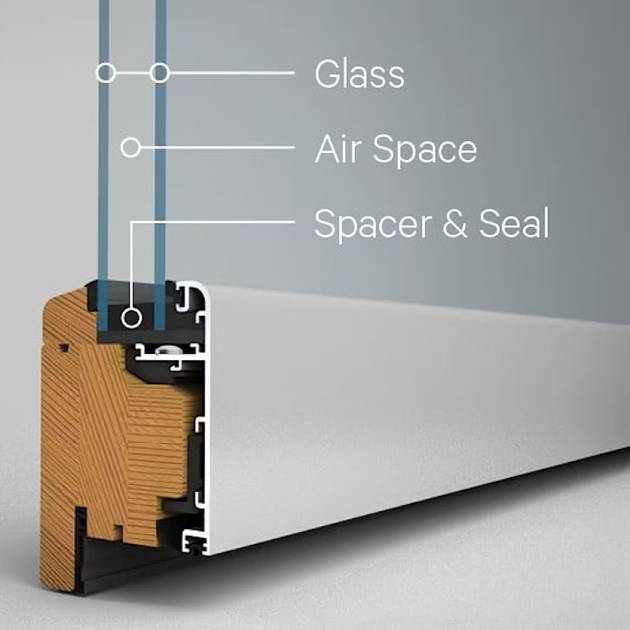

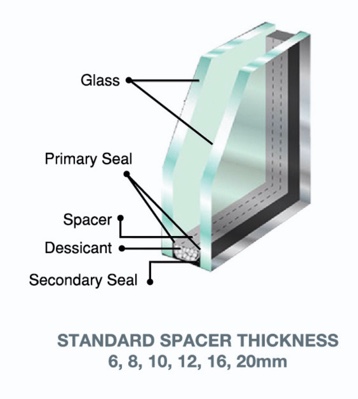

Double Glazing Units (DGU) or Insulated Glass Units (IGU)

Double Glazing Units (DGU) or Insulated Glass Units (IGU)